Using 3D Printers for Affordable Prosthetic Solutions

Leave a CommentAs therapists, we often treat patients using our repertoire of exercises, but occasionally, we are presented with a mega challenge. It’s important at these times to think outside the box and challenge ourselves to tap into outside resources and use cutting-edge technologies available. I’m excited to share with you how I’ve been able to help one of my patients with the help of my community and advanced technology. Warning: This content contains sensitive imagery.

Meeting Manuel

Manuel came to me in December 2019. Manuel was a dishwasher at a restaurant who, in April 2019, cut his finger while washing dishes. This cut developed into a severe infection of the dominant right hand and rapidly spread, causing him to have multiple surgeries for amputations of the thumb, index, middle finger, portions of the hand, and skin grafting on the hand and forearm.

On his hand, Manuel only had the fifth digit (the pinky finger), which actively flexed only 10 degrees at the metacarpophalangeal joint (the big knuckle where your finger bones meet the hand bones). He was unable to move any other joints on the fifth digit. The fourth digit, the ring finger, remained but was only an appendage, meaning he had no motion and no sensation in this digit.

Manuel’s wrist extended to 30 degrees and flexed to 20 degrees. This motion was important to maintain as some prosthetics rely on wrist motion to control prosthetic digit motion. Manuel also had functional forearm rotation.

Starting Hand Therapy

Essentially, Manuel arrived at therapy with only the use of the non-dominant hand. Treatment initially focused on trying to help him gain some functional use with the right hand. I provided him with a universal cuff, an elastic cuff with a small pocket to wear around his hand. A utensil like a spoon could be inserted into the pocket so he could eat without holding the spoon.

Seeking more functions of his hand, I fabricated a device, with a custom simulated thumb made from thermoplastic. With this device in place, he could grasp around light objects and trap them between the splint and his pinky finger. He could hold pegs, a ball, lotion bottles, and he could use the hand for light, functional use for the first time.

I then fabricated a custom device, again from thermoplastic, to help secure a pen in the palm of his hand, which allowed him to write and draw with his dominant hand.

The Search for a 3D Printer

Recognizing that although my thermoplastic thumb was helpful, it was still limiting to Manuel because he could only grasp light objects. Cosmetically, it was unappealing. This began my journey to help Manuel by tapping into experts in 3D printing. I had heard about 3D printing but didn’t know much about it. I wanted something both cosmetic and functional for him.

I looked at the online communities. Using social media, I posted a video of Manuel using my thermoplastic splint/thumb device on several 3D printing Facebook pages. The explosion of responses came from all over the world, including Pakistan, Germany, Canada, all offering to try to help fabricate something for Manuel. I responded to everyone, but there was a consistent theme from respondents. I needed to obtain a 3D scan of Manuel’s hand.

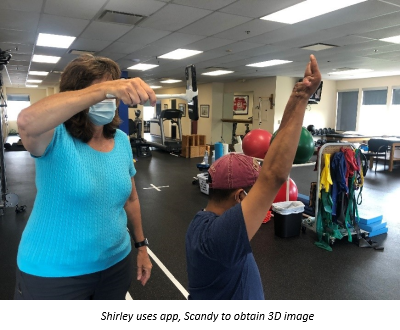

I researched how to do this and decided to try the simplest method, called Scandy. I had Manuel sit on a stool with his right arm extended vertically. He slowly completed a circle on the stool while I used the app, pointing at his hand. This rendered the 3D image I needed. It’s important to note that while the image we attained was fair and certainly something we could use to start, it was not a high-quality image I would rely on to make an accurate prosthetic.

With the 3D image now in my possession, I felt three respondents might be the most helpful. Even with distance being a challenge, I was able to work virtually with the following organizations:

Enable the Future & New Trier High School

Enable the Future is a non-profit organization that fabricates hands for both children and adults worldwide using 3D printing. I spoke with Bob, an engineer who heads up Enable the Future. He agreed to help and take on this project. He has fabricated 27 hands for children, free of charge. Bob, Manuel, and I joined a Facetime call where Bob could see and evaluate what kind of motion Manuel had, so he could better craft a device.

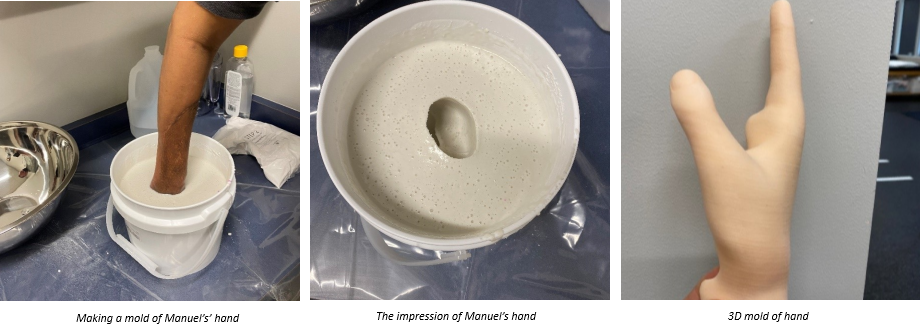

Due to our location in Illinois, Bob put us in touch with Chip, a robotics teacher at a local high school, New Trier, and a volunteer with Enable the Future. Chip came out to my clinic with a kit to help fabricate an exact mold of Manuel’s hand. Manuel was cooperative as we mixed the materials needed. This process is like making a dental impression. The exact mold would later help us as it could be scanned for an exact 3D image. After the mold was fabricated in our clinic, Chip took it back to his high school robotics class. Chip and his students are working on fabricating a functional hand device for Manuel with movable digits (driven by Manuel’s wrist motion). This device will allow Manuel to open and close his fingers by moving the wrist up and down. This device will be fabricated from a 3D printer and will be metallic, so not completely cosmetic but hopefully functional.

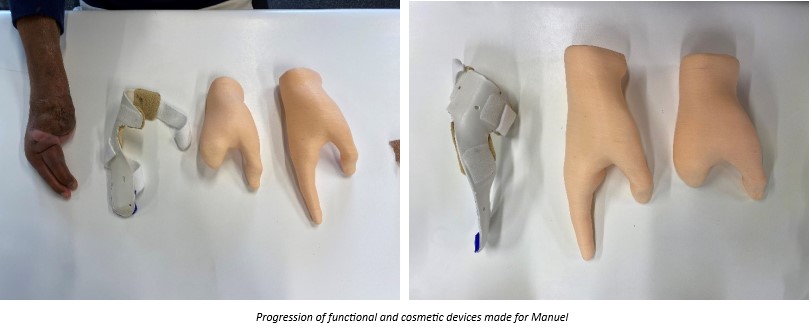

Additive Design

I made the second contact with Marco and Lu, employees at Additive Design in Houston, Texas. Marco is a 3D artist who devoted hours to fabricate a 3D hand that was cosmetically appealing but only semi-functional. The color was more natural to a realistic skin tone. Manuel could wear this 3D hand to conceal his remaining hand’s severely disfigured cosmetic appearance. Function with this device was limited to whatever may fit into the static opening between the thumb and the fingers, holding items like a lotion bottle, folded pad of paper, and a clip as pictured below.

Video of how Marco of Additive Design creating his 3D devices

Video demonstrating how Marco of Additive Design creates 3D devices

University of Wisconsin – Madison

In my initial outreach on social media, someone suggested I reach out to the engineering department at the University of Wisconsin – Madison. I filled out an application for the Biomedical Engineering Department. This past September, a small group of engineering students told me that they had selected Manuel’s hand prosthetic as their class project. We conducted a Facetime call with Manuel and the students to discuss the problems we were having and the hopes of finding a solution that was functional, cosmetic, and low cost.

The Future for Manuel

All three devices are in the works, and we are waiting patiently to see what 3D solutions will be provided for Manuel. We want to thank Enable the Future, the robotics team of New Trier H.S., Additive Design, and the Engineering Department at the University of Wisconsin – Madison for their generous time and help in helping to craft affordable devices for Manuel.

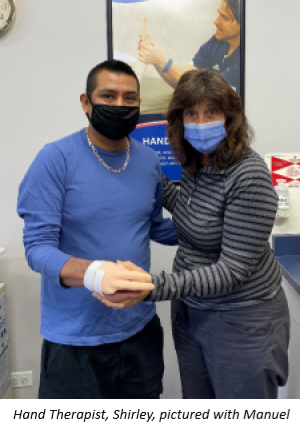

Prosthetics can cost upwards of $30,000. The Hand Therapy team at Athletico is passionate about helping our patients in any way we can. Thank you to Shirley, Athletico Hand Therapist, for going above and beyond in helping Manuel on his journey in finding a functioning prosthetic and helping him return to his daily activities.

To learn more about Athletico’s Hand Therapy services, click here.

Find a Hand Therapist Near You

The Athletico blog is an educational resource written by Athletico employees. Athletico bloggers are licensed professionals who abide by the code of ethics outlined by their respective professional associations. The content published in blog posts represents the opinion of the individual author based on their expertise and experience. The content provided in this blog is for informational purposes only, does not constitute medical advice and should not be relied on for making personal health decisions.